Quality Practices

Reflecting Quality and Responsibility

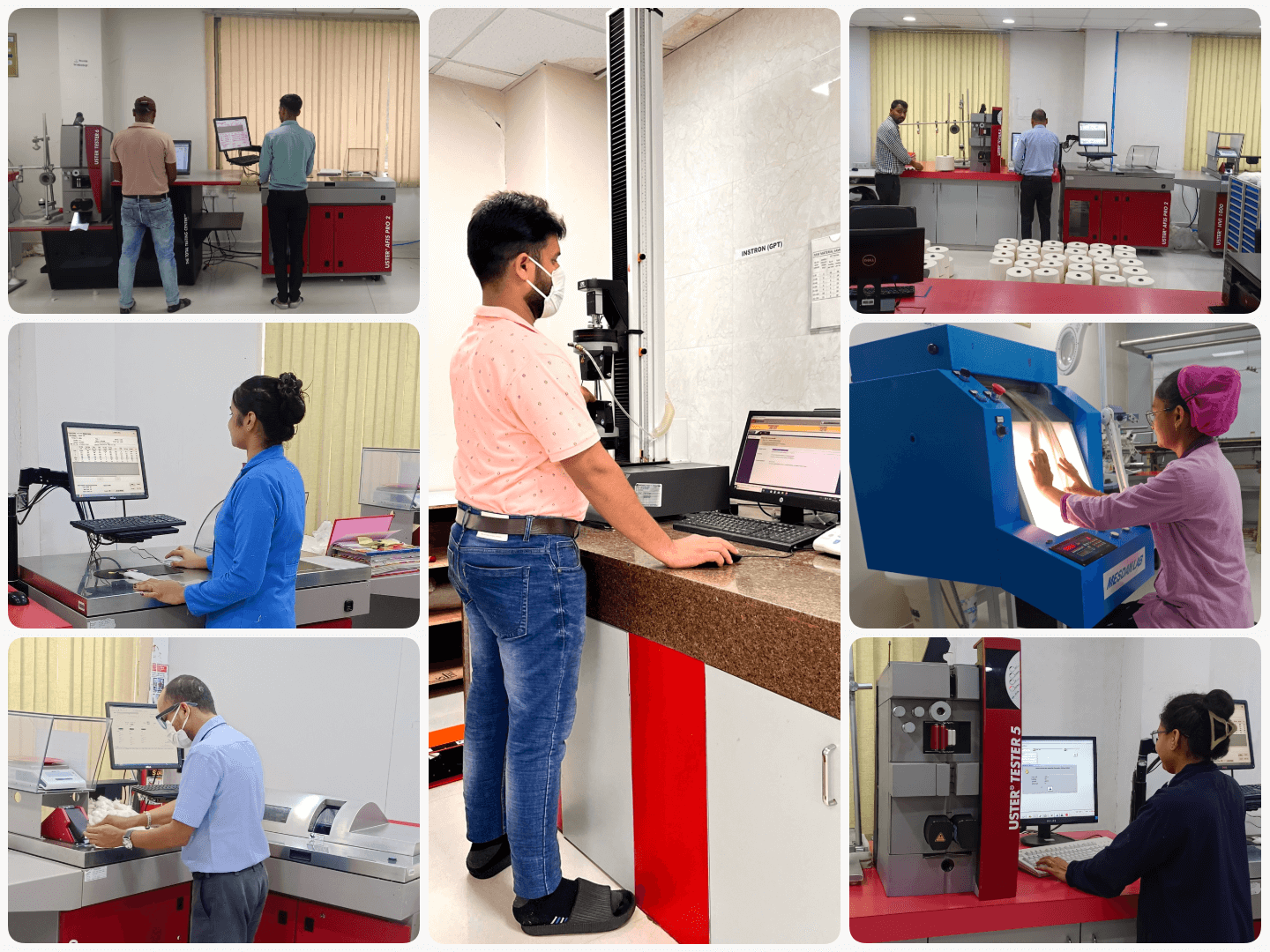

Every yarn produced by Sintex Yarns undergoes a comprehensive and rigorous testing regime at each stage of manufacturing—from raw material selection to final dispatch. Advanced laboratory facilities and standardized testing protocols are employed to evaluate key quality parameters such as yarn count, strength, evenness, elongation, twist, hairiness, and shade consistency.

Advanced Quality Assurance

Every yarn produced by Sintex undergoes rigorous testing and quality checks, ensuring it meets the highest global standards.

Uster Technologies

Tools like AFIS, HVI, UT 6, UTJ, and Classimat 5 ensure precise measurement and quality assessment throughout production.

Contamination Detection

Uster Vision Shield with Magic Eye eliminates impurities for exceptional product quality.

Uster Quantum 3

Delivers real-time monitoring and defect control during winding, ensuring consistent quality in finished yarns.

“Usterized” QC Lab Ensuring Precision and Perfection

Quality lies at the heart of excellence. Backed by advanced Quality Management Systems (QMS) and a steadfast Zero-Defect principle, every strand of yarn produced at Sintex Yarns is a testament to precision and consistency, meeting and exceeding global benchmarks.

“Usterized” QC Lab Ensuring Precision and Perfection

Quality lies at the heart of excellence. Backed by advanced Quality Management Systems (QMS) and a steadfast Zero-Defect principle, every strand of yarn produced at Sintex Yarns is a testament to precision and consistency, meeting and exceeding global benchmarks.

- Continuously enhancing manufacturing processes to achieve operational excellence.

- Consistently maintaining quality throughout the year as a guiding standard.

- Striving for zero defects to uphold the highest levels of product integrity.

- Using advanced systems, seamlessly integrated with quality controls to ensure precision.