Traceability

Traceability at Sintex Yarns

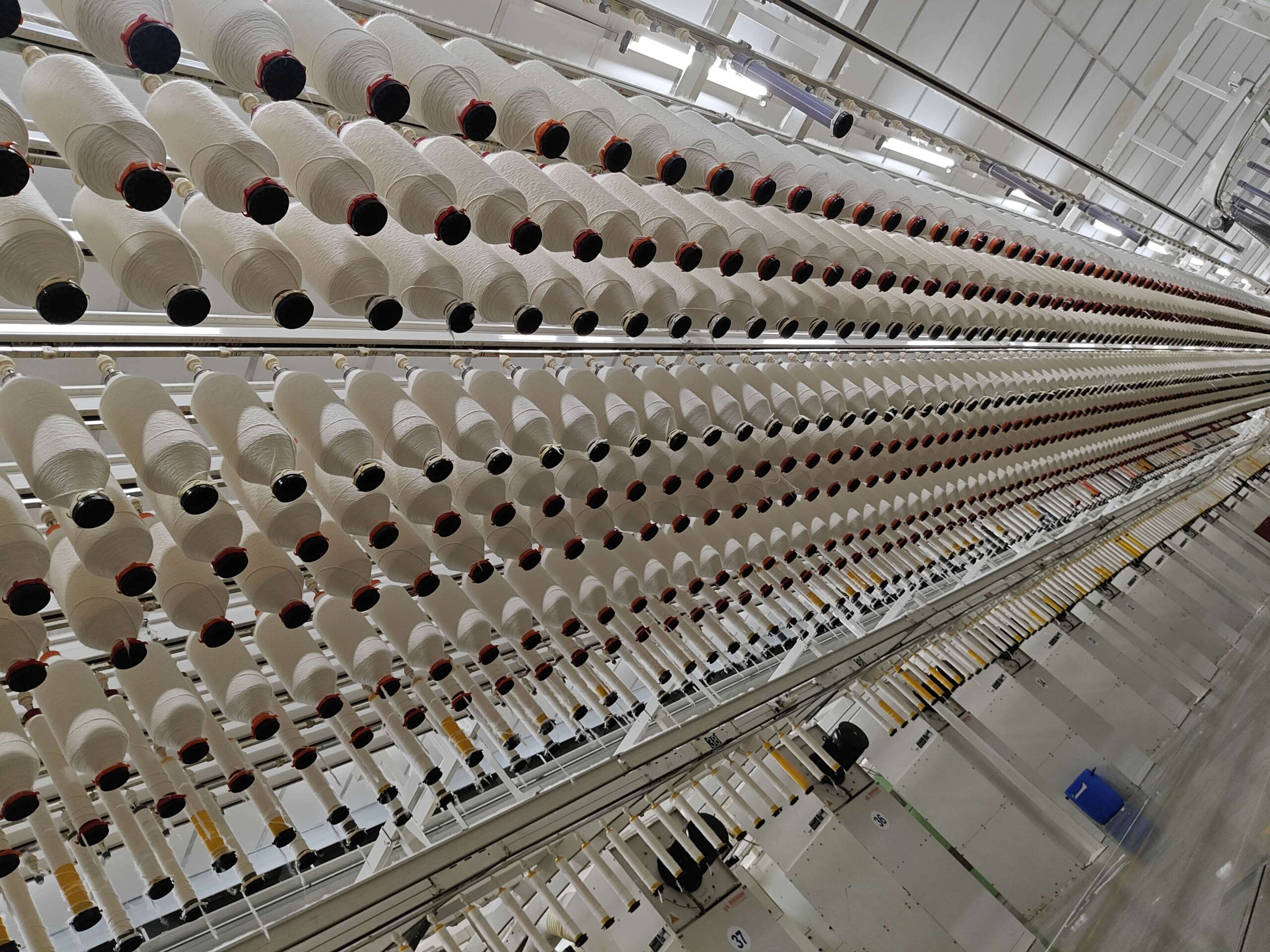

At Sintex Yarns, we believe that traceability is key to maintaining our commitment to quality, transparency, and sustainability. Our traceability system ensures that every cone of yarn we produce can be tracked back to its raw material source, guaranteeing authenticity and compliance with global standards.

Our process includes

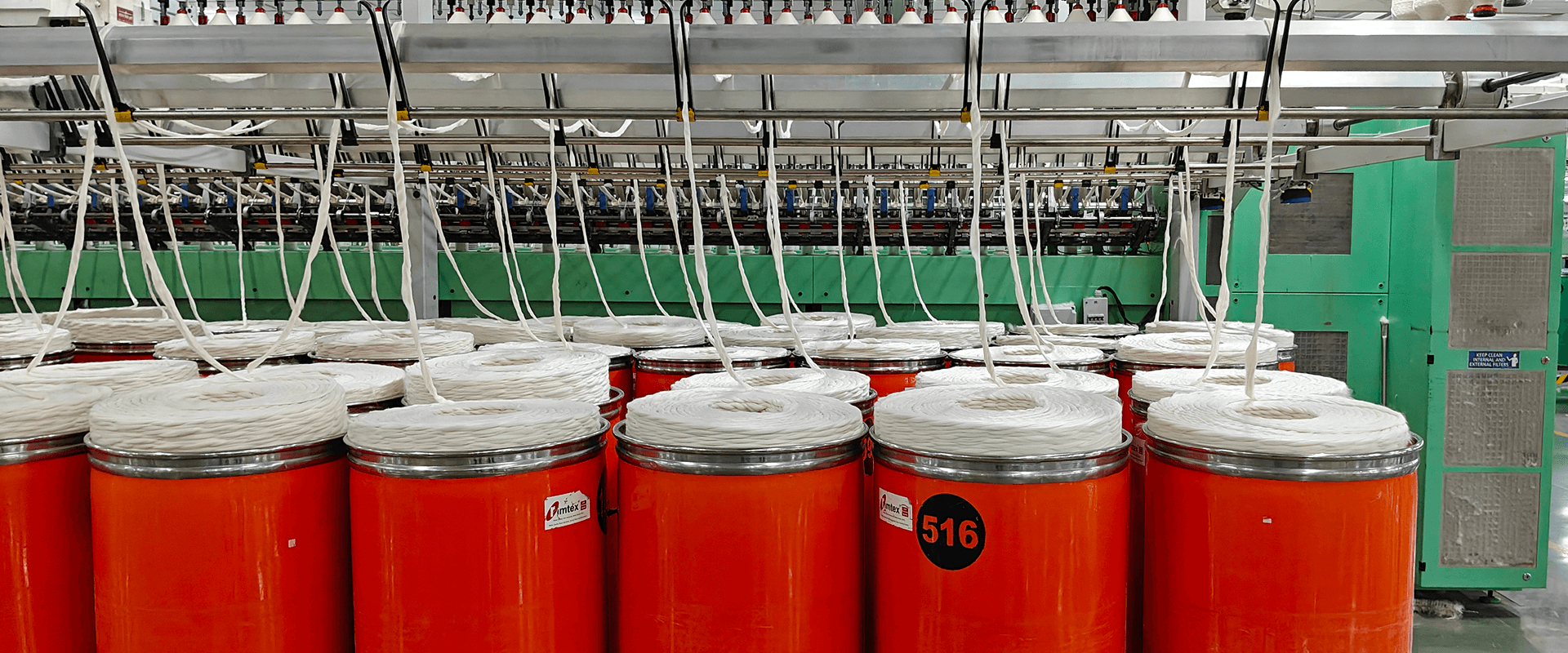

- Raw Material Verification – Sourcing and documenting certified fibers from trusted suppliers.

- Batch Coding – Assigning unique identification codes at every stage of production.

- In-Process Tracking – Monitoring spinning and finishing operations with real-time data.

- Inventory Linkage – Integrating batch codes with inventory movements for full visibility.

- Finished Goods Tagging – Clearly labelling all products with traceability information.

- Data Management and Audits – Regularly updating records and conducting internal audits to ensure traceability integrity.

At Sintex Yarns, our robust traceability practices empower our customers with confidence, knowing they are receiving premium, responsibly produced yarns.

Our process includes

- Raw Material Verification – Sourcing and documenting certified fibers from trusted suppliers.

- Batch Coding – Assigning unique identification codes at every stage of production.

- In-Process Tracking – Monitoring spinning and finishing operations with real-time data.

- Inventory Linkage – Integrating batch codes with inventory movements for full visibility.

- Finished Goods Tagging – Clearly labelling all products with traceability information.

- Data Management and Audits – Regularly updating records and conducting internal audits to ensure traceability integrity.

At Sintex Yarns, our robust traceability practices empower our customers with confidence, knowing they are receiving premium, responsibly produced yarns.